Projects

Home » Projects

All

Water Resources

Sustainable Transportation

Climate Resilience

Energy Transition & Technology

All

Pacific Northwest

Other US

Southern California

Northern California

Smith Canal Gate

Groundwater Replenishment System Expansion

Foster City Levee Improvements

Palisades Fire Cleanup

Miramar Reservoir Pump Station Improvements

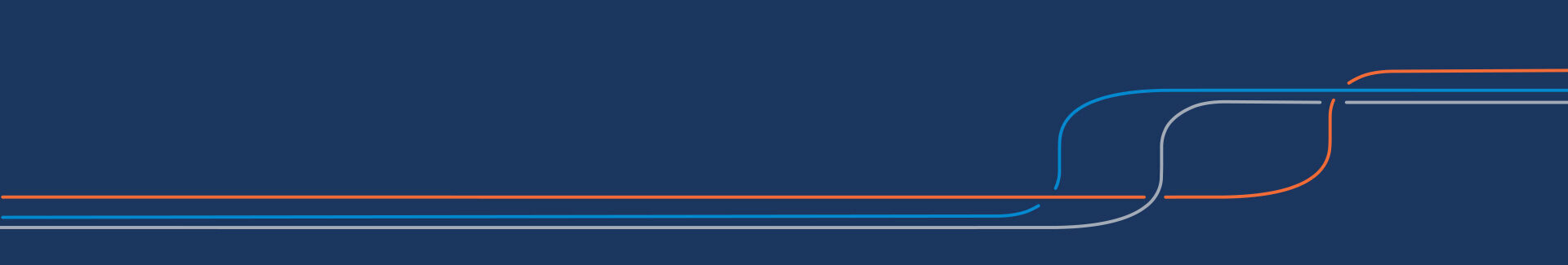

Folsom Dam

North City Pure Water Facility

Terminal 3 and 4 Shore Power

Sunol Valley Water Treatment Plant Ozonation

North Hollywood to Pasadena Bus Rapid Transit (BRT) Project

Murray Street Bridge Seismic Retrofit & Barrier Rail Project

Laguna Treatment Plant Disinfection Improvements Project

Elsinore Valley Municipal Water District Regional Water Reclamation Facility Expansion

Cogeneration System Improvements

Bollinger Canyon – Iron Horse Trail Overcrossing

Golden Gate Bridge Suicide Deterrent System

BART Market Street Canopies

Bay Bridge Lighting Replacement

Bryte Bend Water Treatment Plant Expansion

Soledad Wastewater Treatment PlantSoledad Wastewater Treatment Plant

Robert B. Diemer Water Treatment Plant

Robert A. Skinner Water Treatment Plant

Sunol Valley Water Treatment Plant Expansion and Reservoir

Murray Combined Sewer Overflow Control Facility

Robert Goldsworthy Desalter Expansion

Pure Water Oceanside Advanced Water Purification Facility

Plant 2 Sludge Feed System and Treatment Rehabilitation

Plant 2 Effluent, Building, Site and Security Upgrades

P2-123 Return Activated Sludge Piping Replacement

P2-122 Headworks Modifications at Plant 2

Outfall Low Flow Pump Station

OCSD Central Generation Emissions Control

North City Plant Expansion Site Work and Ozone Relocation

Miramar Clearwell Improvements

J-117A Interplant Pipeline Rehabilitation

Grandsen Pump Station Phase 2

Foothill Water Treatment Plant Pre-Treatment System

Delta Mendota Pumping Plant Project

Santiago Canyon Pump Station Improvements

P1-133 Primary Sedimentation Basins No. 6-31 Reliability Improvements at Plant No. 1

OCSD Plant 2 Sludge De-Watering and Odor Control

Long Beach Municipal Urban Stormwater Treatment Facility

Richmond Wastewater Treatment Plant Critical Improvements

Oceanside Water Pollution Control Digesters

Antioch Brackish Water Desalination Project

Big Tujunga Dam Seismic Rehabilitation

Coleman National Fish Hatchery Water Supply Intake Rehabilitation

Mormon Island Dam Key Block at Folsom Complex

Silver Creek Flood Protection Lower Silver Creek Flood Protection

US 34 Emergency Flood Repairs

Rapid Disaster Infrastructure and Levee Repair

San Vicente Dam Raise

Silverlake Reservoir Phase II Headworks

Natomas Mutual Water Company Riverside Pumping Plant Replacement

Haster Retarding Basin Pump Station

Sweeney-McCune Creek Outflow Recovery & Automation

Sunset Reservoir North Basin Seismic Retrofit

Stony Gorge Dam Modification

Ponderosa Tunnel Project

Mountain Tunnel

Los Padres Dam Fish Passage Construction

Knights Landing Outfall Gate Fish Screen Installation

El Dorado Forebay Dam Modification

Cowlitz Falls Barrier Dam Repair Project

Combined Pumping Plant and Fish Screen Project

Alameda Creek Fish Passage

San Roque Hydroelectric Project

Olmsted Dam

LPV 146 Emergency Levee Improvements

Lewisville Dam Safety Improvements

LaGrange Lock and Dam

Chickamauga Lock Replacement

I-5 HOV Lanes Near Dana Point

Transbay Transit Center Structural Concrete

Illinois Street Intermodal Bridge

LAX Automated People Mover Project

Quint Street Bridge Replacement

Gerald Desmond Bridge

Point Loma Navy Fuel Pier Replacement

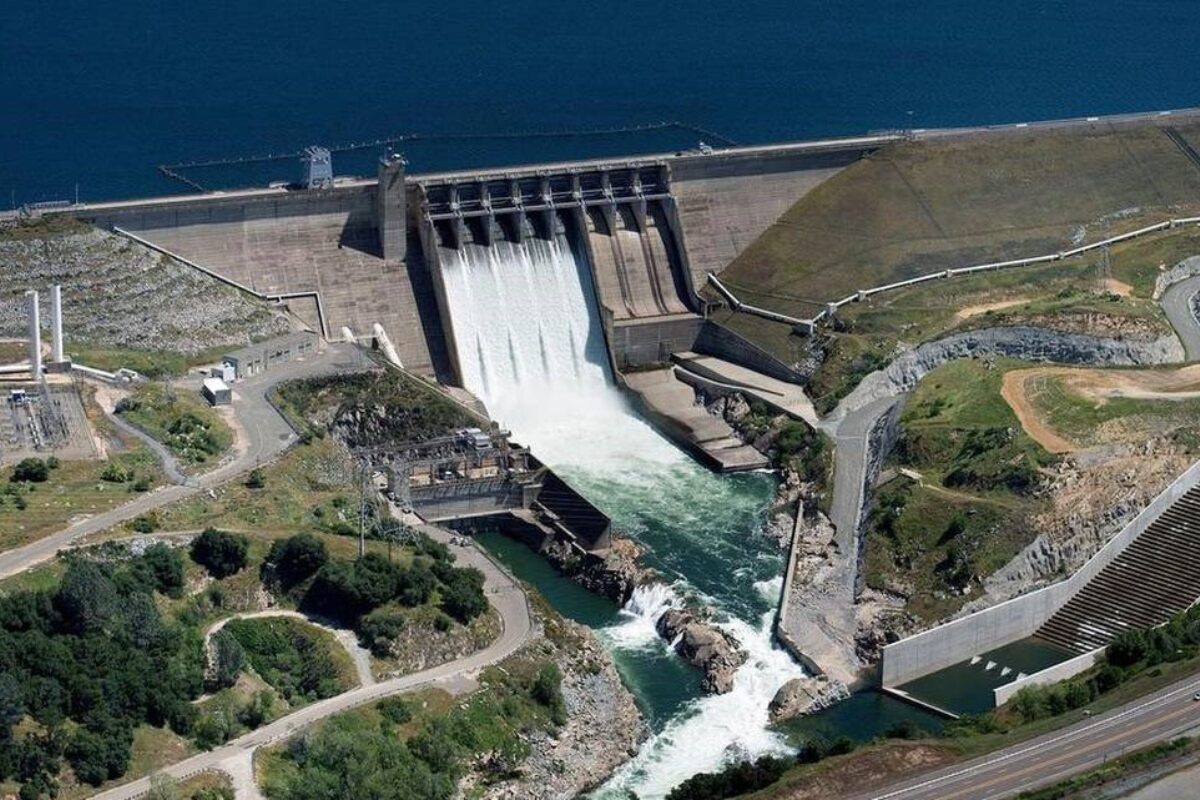

Pier G East Berth Terminal Demolition

Pier G Berths Terminal Redevelopment

LAX West Concourse Electrical Improvements

OCPC Irvine Campus Phase 1

I-70 Eastbound Peak Period Shoulder Lane

Gilcrease Expressway

Malibu Canyon Road & Kanan Dume Project/Mulholland Canyon

Santa Monica Airport Runway Shortening

Port of Los Angeles Berth Reconstruction

Lopez Drive Bridge Seismic Retrofit

LA-405 at San Gabriel River Bridge

Kanan Road T2 and T3 Tunnel Lining Project

Interstate 710 Reconstruction

Del Mar Bridge Replacement

Caltrans Drainage Pump Equipment Replacement

West Howe Street Bridge Seismic Retrofit

San Mateo-Hayward Bridge Span Replacement

Mosquito Road Bridge

Dumbarton Bridge Seismic Retrofit

Crane Cove Park Surcharging and Site Preparation

Curtain Wall Repairs and Backfilling at B Street Pier

Nammuldi Below Water Table Project

Gypsum Stack Tailings Impoundment

Black Thunder Mine

San Fernando Valley Orange Line Bus Rapid Transit

Caltrain Station Pedestrian Underpass

Ocean Boulevard Coastal Bike Trail Connector

Transbay Transit Center Bus Ramps

Muni Third Street LRT Extension

E320 South Bellevue Extension

Caltrain 25th Avenue Grade Separation

BART Fremont Central Park Subway Extension

HART Airport Guideway and Stations

Traction Power Substations Installation

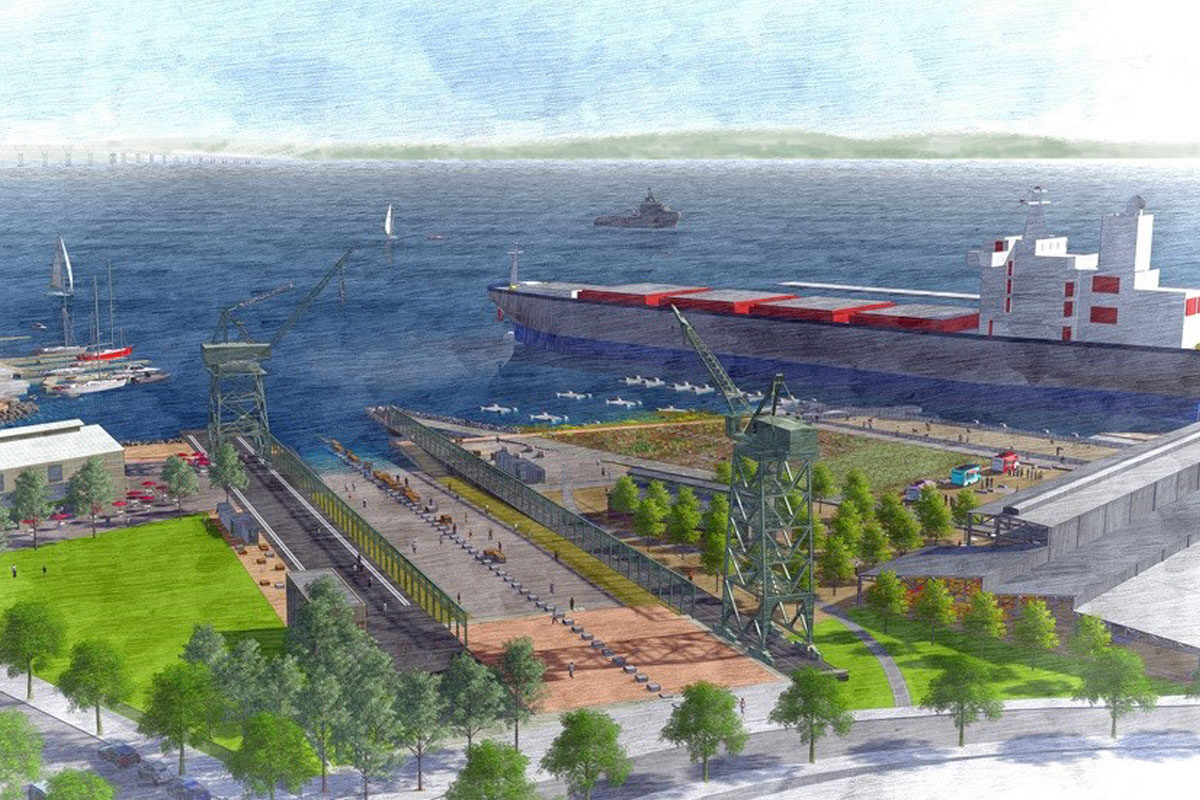

BART Station Emergency Lighting

BART Cable System Upgrade

Metro Gold Line Eastside Extension

Sounder Yard Expansion

Sonoma-Marin Area Rail Transit Package 4

BART West Dublin/Pleasanton Station

BART Silicon Valley Berryessa Extension

Hudson Bergen Light Rail Transit

Dulles Corridor Metrorail Extension, Phase 1

Atlanta Streetcar

San Bernadino Downtown Passenger Rail Extension

El Cajon Third Track Project

Mountain View Light Rail Phase 1 and Signals

BART Warm Springs Extension Access Bridge and Plaza

Oceanwide Center

Denny Network Phase 1 & 2